- Home

- >

- Bulk Manufacturing

Bulk Manufacturing

The full process quality control of injection mold, hardware production, electronics design, assembly, and packaging enables LIEQI to satisfy your customization needs, deliver orders on time and have a more flexible control over overall quality.

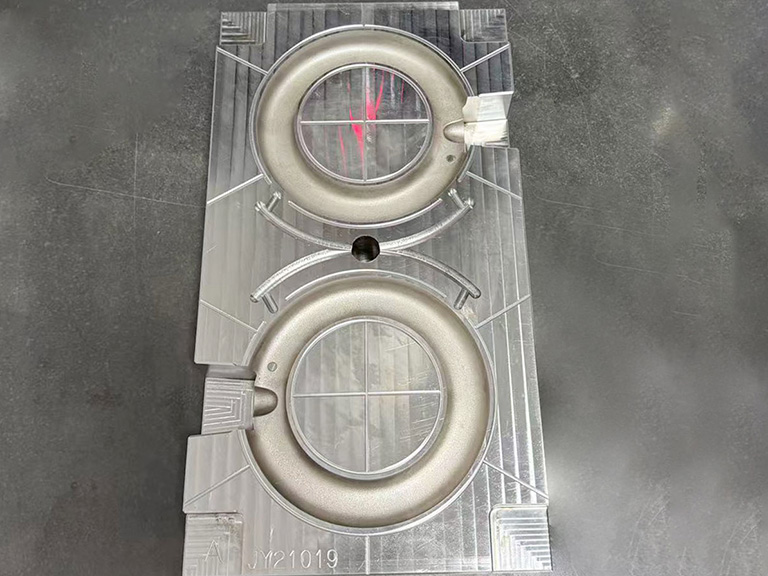

Injection Molding

- With precise mold design, you can customize exclusive plastic accessories such as lamp shell, lampshade and bracket connector of the fill light, to make the product more unique, exquisite and competitive

- Adopt environmentally friendly and recyclable Taiwan CHIMEI POLYLAC® ABS material, which can pass RoHS、CA65、REACH SVHC、UL etc

- There are 10 sets of 350 tons injection molding machines, each capable of producing 2000pcs of fill light shells and 4000pcs of bracket connectors per day, which ensures stable production capacity and on-time delivery

Hardware Production

- The telescopic rod and base of the fill light are made of 100% recyclable steel, which is durable and stable

- The hinges and connectors required for the bracket of the fill light are produced using high-precision CNC lathes to ensure that the led fill light can be adjusted very smoothly and enhance the user experience

- The assembled brackets will undergo the load-bearing test and 2000 times repeated bending test to ensure that they can still maintain its fixed position and not sag after use

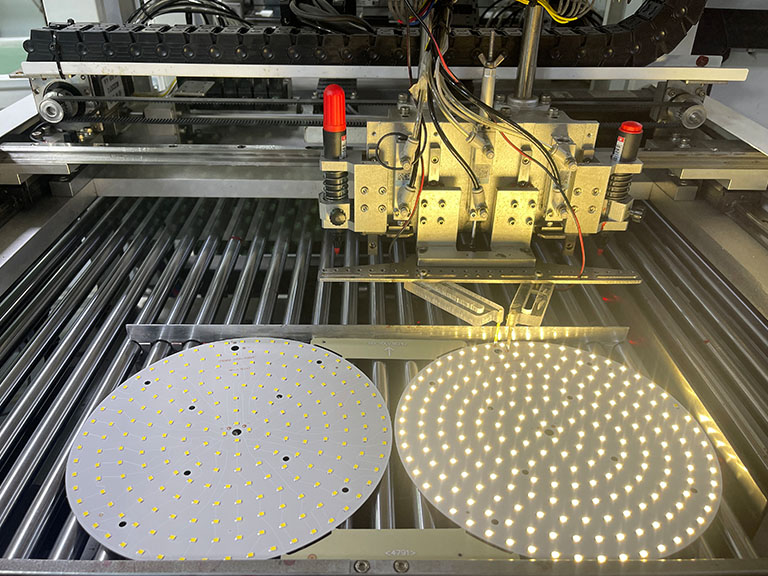

Circuit Control Board Light Board

- Use lead-free soldering materials and recyclable aluminum substrates to produce lamp boards and light control boards in a clean and dust-free workshop, which can be certified by ROHS, REACH, and PSE etc

- Automated LED surface mount technology and intelligent inspection machines can greatly reduce product defect rates

- A professional integrating sphere tester help detect parameters of the led lights such as lumen, color rendering index, and power etc, ensuring the brightness and color requirements of the lights during tattoo, nail art, live streaming, working and other operations

Assembly

- Lamp head assembly: Fix the lamp board on the base and blow dust before pressing the lampshade to avoid black spots affecting the lighting effect

- The bracket and base need to be assembled and tested to make sure the telescopic rod can work smoothly

- The assembled finished fill light will undergo functional tests on lighting brightness and color temperature again to prove that the quality of the fill light can be controlled layer by layer

Packaging

- We have professional designers who can support you to customize the packaging method, packaging layout, instructions, and box inserts of the fill light, making your packaging more eye-catching, stable, smaller in size, and saving transportation costs

- For all accessories of one set of fill lights, we will count them before packaging and weigh them after packaging to avoid missing accessories

- The packaged fill light will undergo a 1-meter drop test to ensure that it remains intact during long-distance transportation